Reverse osmosis membranes RO

Showing all 16 results

Reverse Osmosis Membranes for Water Treatment

The meaning of RO (Reverse Osmosis) is the movement of water through a reverse osmosis membrane when pressure is applied on one side of the membrane. Reverse osmosis is one of the most effective and economical technologies available for removing a variety of impurities from water.

Reverse osmosis is a water filtration technique that uses a thin, semipermeable membrane with tiny pores that allow pure water to pass through while blocking larger molecules such as ionized dissolved salts and other impurities.

Reverse osmosis membranes generate highly purified water and are useful for industrial boilers, drinking water systems, seawater desalination, pharmaceutical production, cosmetics manufacturing, food and beverage processing, among many other applications.

What Advantages Do Reverse Osmosis Membranes Offer in Water Treatment?

– Reduces total dissolved solids: Reverse osmosis is one of the few water treatment processes that can achieve a total reduction of dissolved solids. The few other treatment methods with this capability are generally less efficient than reverse osmosis.

– Cost-effectiveness: Reverse osmosis is popular in industrial settings as it becomes increasingly affordable compared to alternative filtration methods. Reverse osmosis membranes allow industrial plants to treat large volumes of water efficiently, ensuring optimal resource use while staying within budget constraints.

– Environmentally friendly: Compared to other treatment methods, reverse osmosis is also relatively eco-friendly. It consumes less energy than methods like thermal distillation, as it does not rely on energy generation. Using reverse osmosis can help a facility reduce its carbon footprint, protect the environment, and contribute to slowing climate change.

– Removes alkalinity and hardness: Reverse osmosis eliminates calcium and magnesium ions that contribute to hard water, as well as carbonate ions that cause unwanted alkalinity.

History and Origin of Reverse Osmosis Membranes

Reverse osmosis is a water purification process that uses a semipermeable membrane to separate contaminants and impurities from water. The reverse osmosis process was first proposed in 1953 by Charles E. Reid, who sought to obtain drinking water from seawater. For the first 200 years, the osmosis process through semipermeable membranes was only observed in laboratories. However, thanks to the work of Reid and other scientists, the first commercially available reverse osmosis membranes were developed in the 1960s.

Modern reverse osmosis membranes are primarily made of polyamides, cellulose acetate, or thin-film TFM (tetrafluoroethylene and perfluoro-alpha-olefin copolymers), allowing them to offer a high removal rate of salts, organic materials, and other contaminants.

Origin of Reverse Osmosis Membranes

The osmosis process through semipermeable membranes was first observed in 1748 by French scientist Jean-Antoine Nollet. For the next 200 years, osmosis remained a phenomenon observed only in laboratories.

However, the invention of reverse osmosis as a commercially viable process is attributed to Charles E. Reid, who first proposed using reverse osmosis to obtain drinking water from seawater in 1953. At the time, Reid presented his proposal to the U.S. Office of Saline Water but realized the lack of a suitable membrane to efficiently carry out the reverse osmosis process.

Subsequent advancements in reverse osmosis membrane development enabled their commercial application. Since then, reverse osmosis has been used in various water treatment applications and is considered one of the most effective water purification technologies.

Importance of Reverse Osmosis Membranes

The reverse osmosis process has established itself as one of the most effective water treatment technologies. Reverse osmosis membranes are now used in a wide range of applications, such as municipal and industrial water treatment, drinking water production, the food industry, the pharmaceutical production sector, and many more.

More Information in the Following Articles:

Reverse Osmosis Membranes – FiltraShop Online Store

Sources:

Wikipedia. (2021, November 18). Reverse Osmosis. https://en.wikipedia.org/wiki/Reverse_osmosis

United States Environmental Protection Agency. (2018, November). Treatability Manual, Fifth Edition – OSDW Waste Streams. https://www.epa.gov/sites/default/files/2018-11/documents/osdw-treatability-manual-5th-edition_ch13.pdf

Tarleton State University. (2021). Membranes for Water Treatment. http://www.tarleton.edu/COSTWEB/NWRI%20IWWT/industry%20workshops/2014%20main%20workshop%20page/2014%20presentations/Membranes-for-Water-Treatment_greenberg.pdf

-

Reverse Osmosis Membrane – KeenSen 100 GPD

Add to quote -

Industrial Reverse Osmosis Membrane – KeenSen ULP-4040HF

Add to quote -

Brackish Water Industrial Reverse Osmosis Membrane – KeenSen BW-4040

Add to quote -

Hydranautics ESPA CPA LFC Hydranautics Membranes

Add to quote -

CPA2, CPA3, CPA5, CPA6 and CPA7 Hydranautics composite polyamide membranes

Add to quote -

Hydranautics SWC4 SWC5 and SWC6 Reverse Osmosis Seawater Membranes SWC5 and SWC6

Add to quote -

LG BW 4040 ES, 4×40″ low pressure reverse osmosis membranes

Add to quote -

LG SW 400 R membrane, 8×40″ seawater reverse osmosis membrane

Add to quote -

Ultrafiltration Membrane HYDRAcap MAX 40, 60 and 80 Hydranautics

Add to quote -

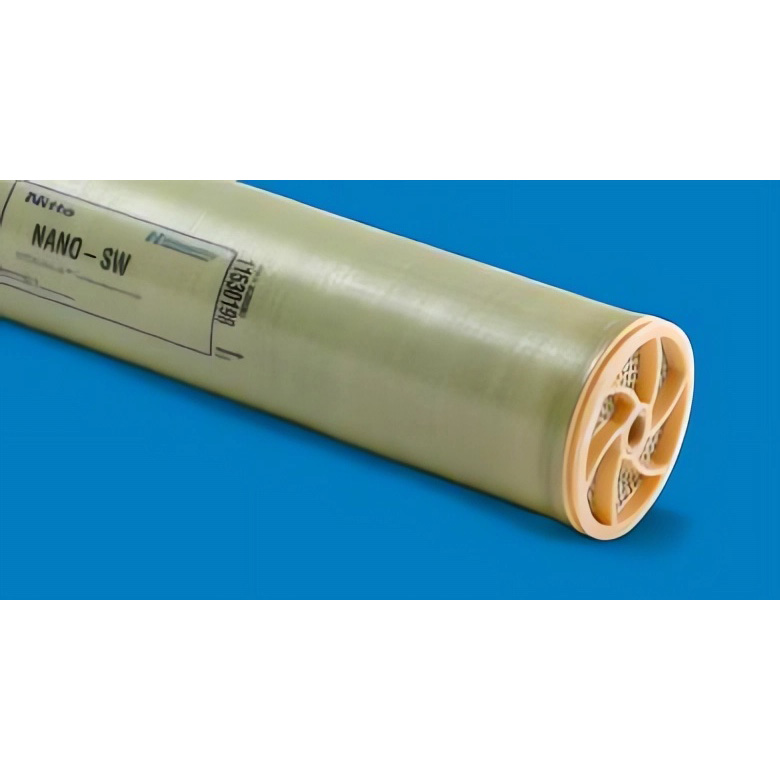

ESNA, NANO and HYDRACoRe Nanofiltration Membrane (NF)

Add to quote -

SanRO HS-4 and SanRO HS-8 4×40″ and 8×40″ Hydranautics Membrane

Add to quote -

Membrane HSRO-4040-FF FilmTec DOW 4×40″

Add to quote -

HSRO-390-FF FilmTec DOW 8×40″ Membrane HSRO-390-FF FilmTec DOW 8×40″ Membrane

Add to quote -

RO-4040-FF and RO-390-FF FilmTec DOW DuPont RO-4040-FF and RO-390-FF membranes

Add to quote -

Hydron BW reverse osmosis membranes

Add to quote -

Residential Reverse Osmosis Membranes Elements RO

Add to quote